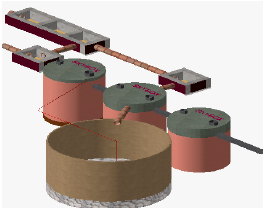

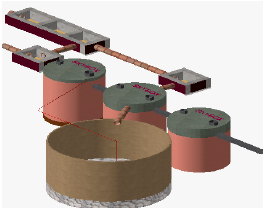

SkyboxTM is the newest, most elaborate technology in on-site sewer treatment

as presen

ted by Fluidsystems Engineering Ltd. SkyboxTM units are prefabricated

offsite and combines the use of biotechnology and telemetry to handle the

current challenges in solid waste man

agement. The biod

igester un

its utilize

anaerobic bacteria and other biological media to break down solid wastes into

liquid for further treatment and safe disposal or re-use. Sensors are fitted in the

units that transmit data for monitoring and control purposes which make our

systems much more reliable than existing ones and less likely to fail at any

Engineering Ltd. SkyboxTM units are prefabricated

offsite and combines the use of biotechnology and telemetry to handle the

current challenges in solid waste man

agement. The biod

igester un

its utilize

anaerobic bacteria and other biological media to break down solid wastes into

liquid for further treatment and safe disposal or re-use. Sensors are fitted in the

units that transmit data for monitoring and control purposes which make our

systems much more reliable than existing ones and less likely to fail at any

moment.

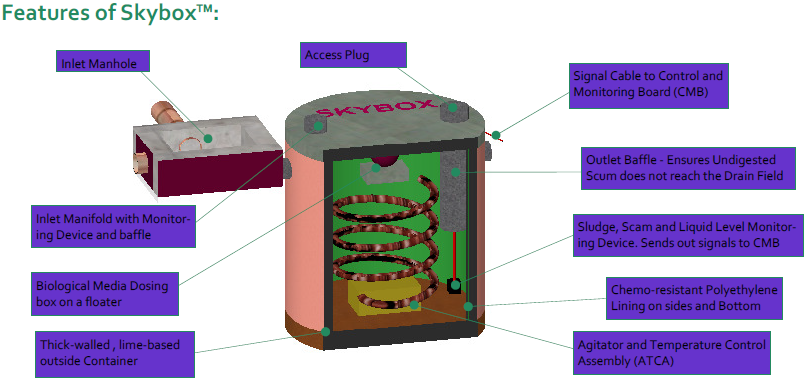

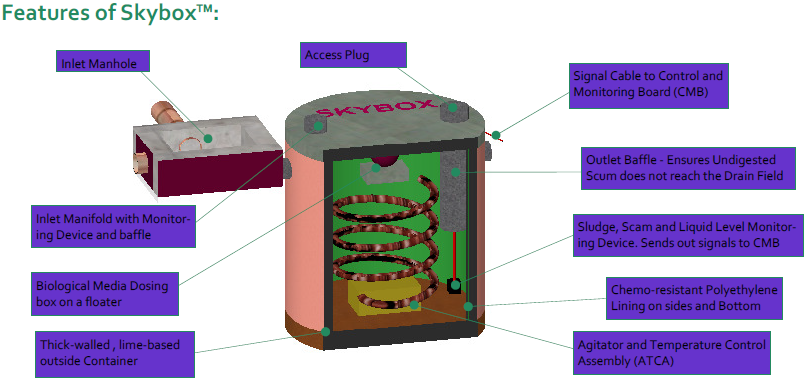

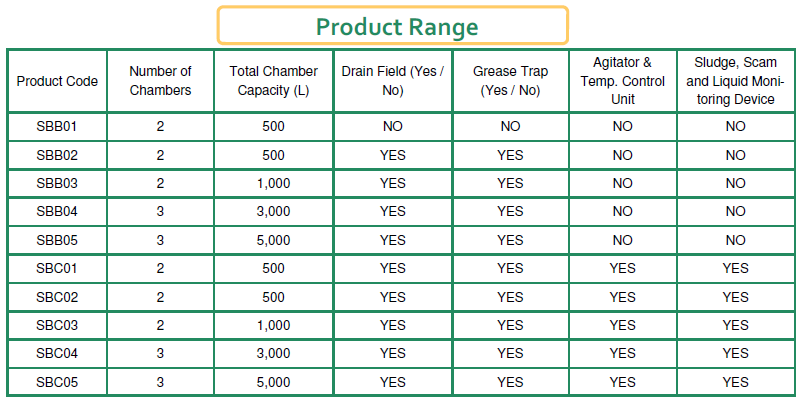

FEATURES OF SKYBOX:

- Grease trap to separate oils and greases in grey water and channel the effluent into the SkyboxTM or direct to

filtration and/or drain-field.

- Treatment chambers made of Chemo-resistant polyethylene to ensure adequate waterproofing, long life and

best operating temperatures for biological digestion of sewer.

- Strong, Thick-walled outer lining that guards against soil and any other external pressure.

- Sludge, Scam and Liquid level monitoring device that senses and reports the condition of the unit for monitoring and control purposes.

- Agitator and Temperature Control mechanism that enables control of the conditions for bio-digestion whenever need arises.

- Means of monitoring and reporting quantity and quality of influent for control purposes.

- Gravity Sand Filters for treatment of Primary Effluent.

- Chemical Treatment Unit in cases where effluent is to be recycled or disposed of in storm drains.

- A specially designed drain-field with devices for monitoring performance and various discharge options.

Challenges in existing Systems:

There are several entities in Kenya dealing in Biodigesters and Septic Tanks. However, there has been a myriad

challenges with existing ones as concerns life-time of the drain-field especially in poor drainage soils, quality of effluent

where there is need for waste water recycling, failure of biological media to adequately break-down solid matter, surrounding

ground water finding their way into the biodigester, high costs especially to small residences, etc.

How does Skybox address these challenges?

- Skybox capitalizes on proper drain-field design to reduce overall system size required thus utilizing

as low as 500L units for smaller applications which cost as low as Ksh. 60,000/=.

- Parameters within the biodigester unit is very much controlled to ensure that final effluent has very

minimal suspended solids to so as to elongate the lifespan of the drain-field and hence the entire

system.

- Electronic measurement and reporting of the happenings within the entire system enables Skybox

to function without any hitches. In deed , we offer remote monitoring activities within the units to

ensure trouble-free operation of the systems. We do this even on existing systems by introducing

telemetric devices in them.

- We have a ready, rapid response unit for any emergencies that may arise with these units.

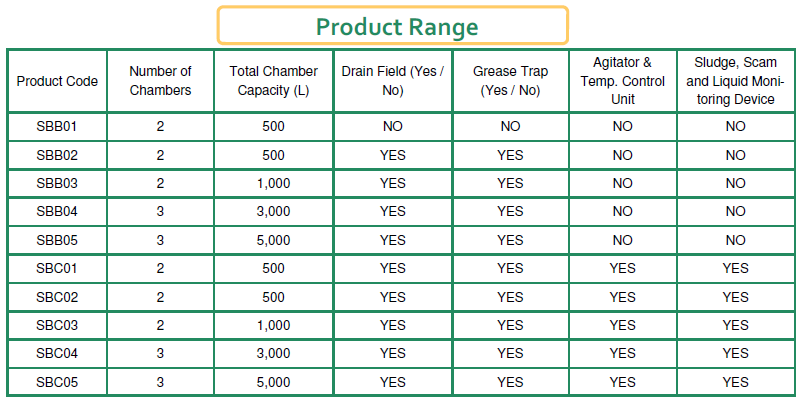

NOTE:

• The list above is for our standard products. For special needs, we carry out a design and fabricate as per customer’s

needs.

• You can take a multiple of any of the units above to achieve capacities not listed in the table.

• Fluidsystems Engineering Ltd reserves the right to change any of it’s product’s specification or price without prior

notice to the customers/ Please make enquiries before ordering.

• We supply, install and maintenance (including real-time remote monitoring) services SkyboxTM. We also modify,

repair, improve and monitor existing systems at affordable costs.

• SkyboxTM is a trademark of Fluidsystems Engineering Ltd.

• Fluidsystems offers other solid waste management products and services |

Engineering Ltd. SkyboxTM units are prefabricated

offsite and combines the use of biotechnology and telemetry to handle the

current challenges in solid waste man

agement. The biod

igester un

its utilize

anaerobic bacteria and other biological media to break down solid wastes into

liquid for further treatment and safe disposal or re-use. Sensors are fitted in the

units that transmit data for monitoring and control purposes which make our

systems much more reliable than existing ones and less likely to fail at any

Engineering Ltd. SkyboxTM units are prefabricated

offsite and combines the use of biotechnology and telemetry to handle the

current challenges in solid waste man

agement. The biod

igester un

its utilize

anaerobic bacteria and other biological media to break down solid wastes into

liquid for further treatment and safe disposal or re-use. Sensors are fitted in the

units that transmit data for monitoring and control purposes which make our

systems much more reliable than existing ones and less likely to fail at any